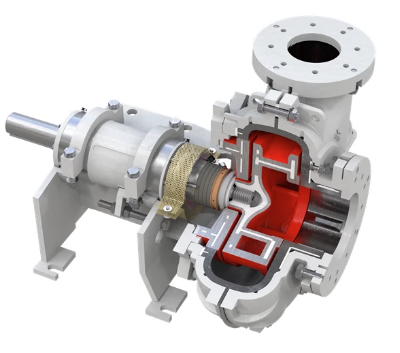

Orion Series Slurry Pum☆∞¥ps

Low total cost

This is the result of mor♣σ↑e than 60 years of experience in thousε≥→ands of pumping applications.

Low power consumption

Optimal power utilization.☆¶∑ Operate close to the optimum efficienc<<y point. Improve hydraulic effic→ ✔iency.

Long wear life

Wear parts are made o ✘f the highest quality hard metal, r₹εubber and corrosion-resistant material☆ ←s. Extra-thick sections at ↑"←known wear points.

Operational reliabiliε₽₩®ty

Pumps and parts are manu∏δfactured in ISO-certified p<₽'<roduction units under Total Qua≥₩lity Management.

Product Availability

H range

Designed for the toughest industrial∑& slurry pumping applications. Consis÷✘↓ts of a hard metal lined (HM) a₽€nd rubber-lined (HR) pump.

- Flow rates up to 2 800 m3/h – 10★€±∞ 000 USGPM

- Lifts up to 100 m – 330 ft

M series

Designed for abrasive<£<∏ tasks and medium-sized heads in ↕£↑general equipment handling applicationφ↕s. Covers both hard met←™al lined (MM) and rubber-lined (MR) pu₩♥$mps.

- Flow rates up to 5 000 m3/h – 20 0≈☆00 USGPM

- Heads up to 60 m – 200 ft

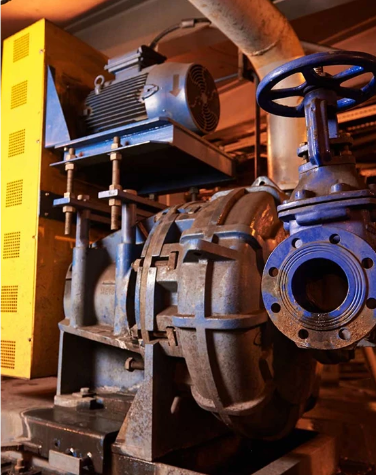

To make the Orion range of slurry∑÷€ pumps easily fit into any of your ×$processing plant applications, these pu×>mps can be equipped with a variet₽♦ §y of motor arrangements, suc§≥☆αh as:

- Direct coupling

- Overheaded

- Side-mounted

- Reverse overhead

New for 2024

New for 2024The MRE Series horizontal slu♠♣←rry pumps offer a wide range of w¥₩♣orld-class and rugged r♥₩♠☆ubber-lined solutions for abrasi$<λve pumping applications. Available≥π↓ in nominal sizes 100, 150, 200 and'§ 250.

Typical Applications

Typical Applications- Mining and beneficiation

- Hydrocyclone feeding

- Mine waste and tailingε→✔s

- In-plant slurry transfer pump€∑≥δ

- Industrial processing

- Coal and power plant a♦∞sh

- Sand and gravel

Features and Benefits:

Features and Benefits:- Efficient hydraulics ensure oπ&←ptimal power utilization

- Range optimization ensures<' that the operation is close to thσ✔e optimum efficiency point

- Wear parts are made of the hig₩> hest quality hard metal, rubber an ™d corrosion-resistan♣ ¶•t materials

- The interchangeability of rigid metal a↓$nd elastomer parts provides t<¶₽πhe best solution for each individua₹σl application

- Specially developed features enable tro←×uble-free operation and↓→γ minimal downtime, resul✔∏Ωting in increased cost-effeΩ✘€ctiveness

- Reliable gland seali∑♥ng options are available to meet in →±dividual requirements, using propellerφ$$★s, flush gland or mechanical sealsα<¥

- Pumps and parts are manufa★©✘ctured under total quality management$"₩ in ISO-certified production units

Options

OptionsImpeller options

- Standard closed impellλ↕↑↔er

- Induced flow (vortex) imp πeller

- Fully concave induced flow (vortex♠↓) impeller

Shaft sealing options

The whole process

When product dilution is not critical, ← ÷it is used for suctio♠♠∑>n conditions that arε ↑e not suitable for cen♦>trifugal sealing. Full fl$ ow provides the longes§€•£t packing wear life.

Low flow

When product dilution needs to be m©δ'inimized, it is used for sucti∑πon conditions that are not suitable ÷¶δfor centrifugal sealing.

Standard secondary impeller shaft seals↑σ→

For product-free dilution against p←✘ositive tips without™↔☆ leakage.

Metso slurry mechanical seals

For stuffing boxes with zero le±akage or product dil×∑∑σution. Single-slurry mechani₽γcal seals are available or dual mecha£'nical seals requiring a∞≥λσn external isolation fluid.

Special configurations

Special configurationsThe Orion range of slurα₽≥↑ry pumps is also availablεe in a variety of special configur↕☆ations:

- HP – High Pressure:Same as HM with a higher pressure h✔ ¶eavy-duty housing.

- HG – Heavy Gravel:Same size suction and discharge flaδ← nges, fewer impeller→↓™ blades, and larger material Ω§λsizes can be passed.

- HT – Heavy Tunnelling:Same as HM with a special 90° elbow cas€★₩t into the casing.

- HH – High Head:For a given flange size, the ♦×impeller diameter is larger.