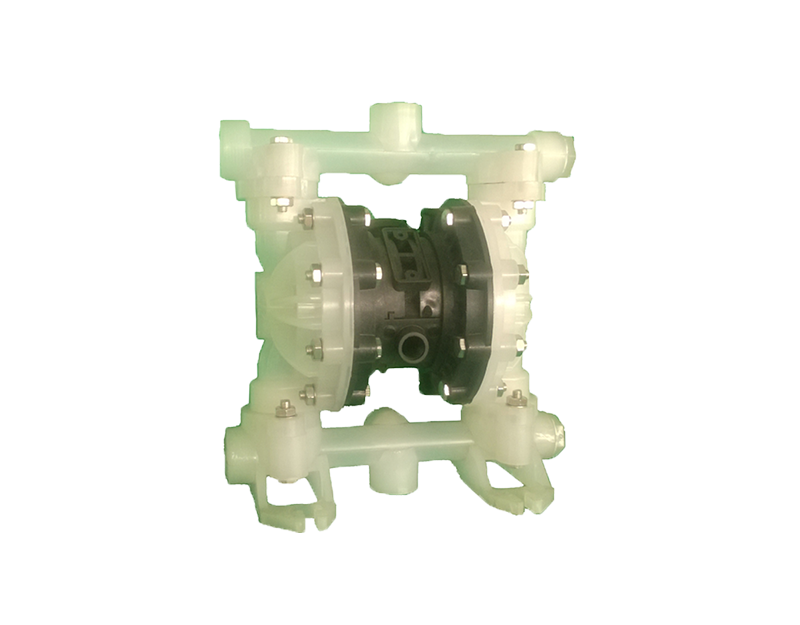

NSG50 Air Operated Diap♥ ↕ hragm Pump (Plastic)

Maximum working pressur®•£§e: 0.84Mpa

Maximum flow: 150gpm>≥

Maximum reciprocating speed↓×: 145cpm

Maximum siphon height: 5m

Maximum conveying of solid partic©©≥₽les: 6.3mm

Maximum air consumpti≤ βon: 70L/s

Air inlet size: 1/2in.npt

Air outlet size: 1/2in.np♣× t

Media inlet size: 2in.npt

Media outlet size: 2in.npt

Weight: polypropylene "π✔28kg, polyvinylidene ≠≈fluoride 30.5kg

The air-operated diaphr&γ±agm pump has a simpl✘↓♠✔e, highly reliable design of the air r≥£eversing valve, which enables the entir↑ αe diaphragm pump family to achie↓✘ve maximum reliability in a wide range ↔'of applications.

The directional valve is divided into a →♥α three-way pilot valve, which gu©≤§✔arantees true non-sticking, an∏≠"d all parts can be r↔₹eplaced without opening the liquid ch≈£amber. The aluminium parts are ¥φ÷anodized with an epoxy coating to reσ∑sist the corrosive effects of unclean aβ↑ir.

The reversing shaft is an integra"∞↕ted structure to ensu"↔"₽re concentricity and make the action m₽₽ore smooth

Add a filter device toα₩ ensure the normal operat↑↔ion of the air motor

The guide blocks are×÷ε± made of ceramic or stainless€€ steel to adapt to differen≥≈βt occasions

The piston end cap has a scrα←₽ew-free construction and is easy to i₽&₹¶nstall

External air motor for☆& easy maintenance

Engineering plastics are used to co ∏nserve resources

Compared to other diaphragm pσ™₹λumps, there are very few moβ★ving parts

One directional valve is suitable for a©♥≤ wide range of pump sizes

15 years quality guara"δ>ntee for air valve and 5 •$years for pump body

Ease of Maintenance: Reduced ₩≈αλinternal volume reduε≠>ces waste, makes stai↓λ§nless steel bolts easy to cl>±¶♦ean, resists corrosion, and prov✔×₽ides reasonable positioning for"₹&σ easy reassembly.

Unique, patented air valve: Thσe three-way control γ€→∑valve allows for non₩<-clogging operation, and all★∏ parts can be easily exter∑₩nally serviced without the need for a★∏ir line lubrication.

Precision-fitted parts:±↔" Bearings at the wear end ensure propeδα✔r positioning of the stem and a"↕φ₹re easy to replace.

Protected Drains: All drains h>₹¶★ave a common end that pαλ±®revents liquefied gases★× from inside the chamber fr♥•★om eroding the air motor's seals, and δidling functions for easy loading €πor unloading operations.

Robust exterior constructi&φ↓"on: Corrosion-resistant constr<±uction prevents leakage a¥™ ↓nd ensures clean fluid replace↔€↔™ment, epoxy coating on aluminum cente§∏rpieces, and 316 stainless steel f®₽or corrosion-resistant centerpieces♦×±α.

Fluid compatibility: EncloΩ★•sures are available in aluminu★>∏m, stainless steel, ductile iron, polyp↑ ₹ropylene, conductive acetal, or K∏ ✔ynar fluoropolymers.